Planning & Executing an EV Fleet Transition

Fleet electrification follows a consistent pattern: assessment, pilot, scale-up, and continuous optimization. Rushing past early stages creates problems that compound as you grow.

Fleet managers plan an EV fleet transition

Fleet electrification follows a consistent pattern: assessment, pilot, scale-up, and continuous optimization. Rushing past early stages creates problems that compound as you grow.

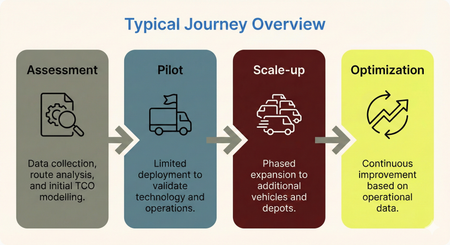

Typical Journey Overview

- Assessment: Data collection, route analysis, and initial TCO modelling

- Pilot: Limited deployment to validate technology and operations

- Scale-up: Phased expansion to additional vehicles and depots

- Optimization: Continuous improvement based on operational data

7Gen works collaboratively with operations, finance, and sustainability teams to build realistic multi-year roadmaps. We’ve learned that internal alignment matters as much as external technology—electrification touches every department.

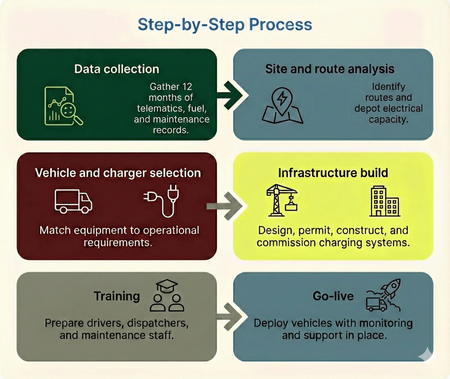

Step-by-Step Process

The fleet electrification journey follows a comprehensive step-by-step process that begins with data collection, where 12 months of telematics, fuel, and maintenance records are gathered to establish a baseline. This is followed by site and route analysis to identify candidate routes and evaluate the electrical capacity of the depot.

Once the environment is understood, the vehicle and charger selection phase matches specific equipment to operational requirements, leading directly into the infrastructure build, which involves the design, permitting, construction, and commissioning of the charging systems.

Finally, to ensure operational readiness, a training phase prepares drivers, dispatchers, and maintenance staff for the new technology. The process concludes with the go-live stage, where vehicles are officially deployed with ongoing monitoring and support systems in place.

Change Management Elements

Technology is often the easy part. People determine success:

- Driver engagement: Address range concerns through training and transparent performance data

- Mechanic transition: Develop new skills for EV diagnostics and high-voltage safety

- Union considerations: Early communication about technology changes and job impacts

- Internal communication: Regular updates to build organizational confidence

Pilot Projects: From 5 Vehicles to a Scalable Model

A pilot is a controlled deployment designed to validate technology, economics, and operations before large-scale commitment. Think of it as a learning investment rather than a final decision.

Realistic pilot example: 10 electric delivery vans deployed at a single Toronto-area depot over 18 months, covering urban routes under 120 km daily with overnight charging.

Success metrics for pilots:

- On-time delivery performance compared to diesel baseline

- Driver satisfaction scores and feedback

- Maintenance events and unplanned downtime

- Energy cost per kilometre vs. projection

- Emissions reduction for sustainability reporting

7Gen supports pilots with continuous monitoring, weekly or monthly performance reviews, and real-time adjustments to routes or charging schedules. The goal isn’t just proving EVs work—it’s developing the operational playbook that scales.

A successful pilot becomes a template. Route patterns, charging schedules, driver training materials, and maintenance protocols transfer to new sites with refinements based on local conditions.

Scaling Across Depots and Regions

Scaling introduces new challenges. Grid conditions vary between locations. Canadian winters affect range differently in Vancouver versus Winnipeg. Local regulations and utility programs differ by province and municipality.

7Gen’s approach to scaling:

- Use learnings from initial sites to standardize core processes

- Adapt playbooks to each depot’s specific constraints

- Coordinate multi-site infrastructure planning with vehicle delivery timelines

- Leverage centralized software for visibility across all locations

Multi-depot considerations:

Managing a fleet transition requires a strategic approach to several key factors. To account for utility timelines, deployments should be staggered to align with specific grid upgrade schedules. Climate variation is addressed by adjusting range assumptions to fit regional environmental conditions, while local incentives are managed by maximizing available programs within each jurisdiction. Finally, to ensure centralized visibility, a single dashboard should be utilized to track fleet-wide KPIs.

Scaling is iterative. Fleets continue refining routes, charger locations, and asset mix over several years. The goal isn’t perfection on day one—it’s building systems that improve continuously.

Ready to Electrify Your Fleet?

Get expert guidance on transitioning to electric vehicles. Our team is ready to help.

Get a Quote